It’s been a while since 3D printers became available and started allowing people to create 3D objects in the real world right from their own home.

If you’re interested in getting a rundown of what 3D printers are, how they work, how much they cost, and what you could do with them, you’ve come to the right place.

What is the 3D printer?

A 3D printer can produce physical objects using a digital model. Plastic is the most common material. The result is usually plastic. It may have rough edges or be a single colour. Despite those limitations, holding a real-world copy of a 3D model makes it easier to get a sense of what works and what doesn’t.

The best 3D Printers are able to create parts that can be used in everyday life. The industry’s long-term goal is to prolong the life of consumer goods by allowing anyone who needs a replacement part to print it.

A 3D printer is not only useful for recreating missing or damaged parts, but can also produce enough pieces to assemble an entire product. This technology allows for rapid prototyping and can be used to make changes quickly to the design without having to invest in expensive injection molds.

The 3D printer is also used in commercial manufacturing. In the case of small-scale production, 3D printing can be a more cost-effective alternative to traditional methods.

How does a 3D printer work?

Fused Deposition Modeling is the most common 3D printing design. It’s similar to an inkjet. The FDM printhead is a side-to-side moving device that deposits material onto a moving platform. A 3D printer, unlike an inkjet printer that sprays ink onto paper, extrudes hot plastic on a glass or metal plate.

Two computer-controlled electric motors control the flow of plastic across the entire length and width, one for each printhead. To add height, a motor raises the rail on which the printhead is positioned.

3D printing, when compared to other manufacturing techniques, is slow. It can sometimes take hours to bring an object into the third dimensional. It can be made faster by extruding a larger amount of material, but this increases the layer height. The result is a print with a rough texture. In addition to the smooth surfaces, vertical angles and curves also have steps.

In the second most common consumer 3D printing type, light is used instead of heat to shape plastic. A resin 3D Printer, also known as an UV-light projector, uses UV to project images onto a liquid resin. The resin reacts to the wavelength of UV light and solidifies.

The resin 3D printing process is usually faster, as it cures an entire layer all at once. However, UV resin usually isn’t as durable as the thermoplastics used for FDM 3D printing.

FDM filaments can be made from a more durable plastic or other materials such as metal, glass and ceramic. The 3D printer component takes on the appearance and characteristics of the materials. With specialized 3D printers, it’s possible to create objects in a variety of materials, even cheesecake.

What can a 3D-printer make?

Commercial 3D printers are capable of producing almost anything. Some 3D printers melt metal using powerful lasers, creating parts that can be used in rockets or other rugged machinery.

The size and material of consumer-grade 3D printing devices are limited. The size of the print plate determines what a 3D object can measure in terms of length and width, while its height is determined by the height of the 3D printer.

3D printed objects can usually fit into your palm. Consumer 3D printers that are larger can handle objects up to a cubic feet. It’s also possible to make a large object by assembling several smaller parts.

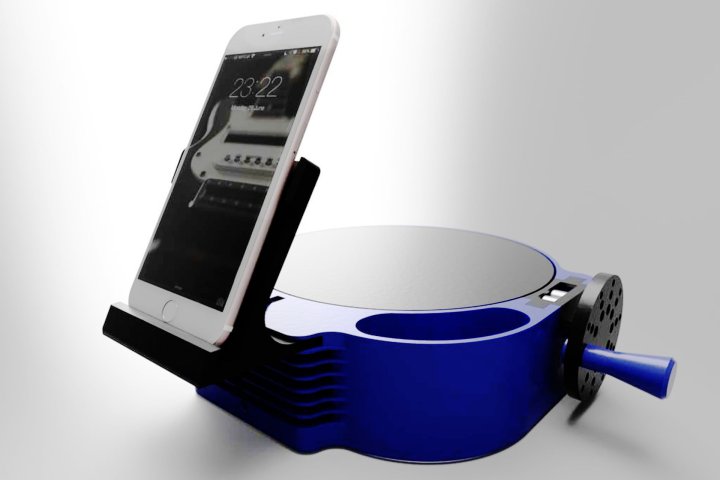

The most popular 3D products include a whistle and a phone stand with a turntable that allows you to scan objects in 3D. There is also a digital sundial, which uses the sunlight to create a shadow, which tells the time with easy-to-read numbers.

The possibilities are limitless. For example, Thingiverse is one of the largest libraries of 3D objects designed for 3D printing, with over 2.5 million digital files — and most are free.

With the rise of generative AI, it’s now possible to create 3D objects with text prompts. At present, AI isn’t creating designs optimized for 3D printing, so you would need to convert the file to a compatible format and process it through a 3D-printing app before use.

How much do 3D printers cost?

3D Printers start at around $100. That’s a great price for such a powerful technology. Advanced models are more expensive, but have larger print plates and faster printing speeds.

Around $300 will get you a great consumer 3D printer. If you are a 3D printing enthusiast, you can get a faster and bigger printer for $500 to $1,000. Commercial 3D printers cost between a few thousand and over one million dollars.

Be aware you’ll need supplies and might want accessories for your 3D printer, so keep a little more in the budget for those added costs. FDM filaments and UV resin are relatively inexpensive, but are sold in bulk, so you’ll spend at least $20 to get the necessary supplies.

Accessories can include an enclosure for reducing the noise level of an FDM 3D print, better building plates, cooling fan to speed up printing, UV lamps to harden resin and tools to clean and maintain 3D printers. You usually don’t need accessories to get started, and some 3D printers come with a small amount of filament or resin to create the first few prints.

A 3D printer unlocks the potential to inexpensively create replacement parts, duplicate designs that are available online, or prototype entirely new products that don’t yet exist. This amazing technology has existed for decades, but became more affordable and easier to use only in the past few years.

If you haven’t explored 3D printing recently, it’s time to take another look. If you’re new to 3D printing, now is a great time to get started.

Editors’ recommendations