Form-memory polymers or shape-shifting supplies are sensible supplies which have gained important consideration inside supplies science and biomedical engineering in recent times to construct sensible buildings and units. Digital gentle processing is a vat photopolymerization–based mostly methodology with considerably sooner know-how to print a whole layer in a single step to create sensible supplies.

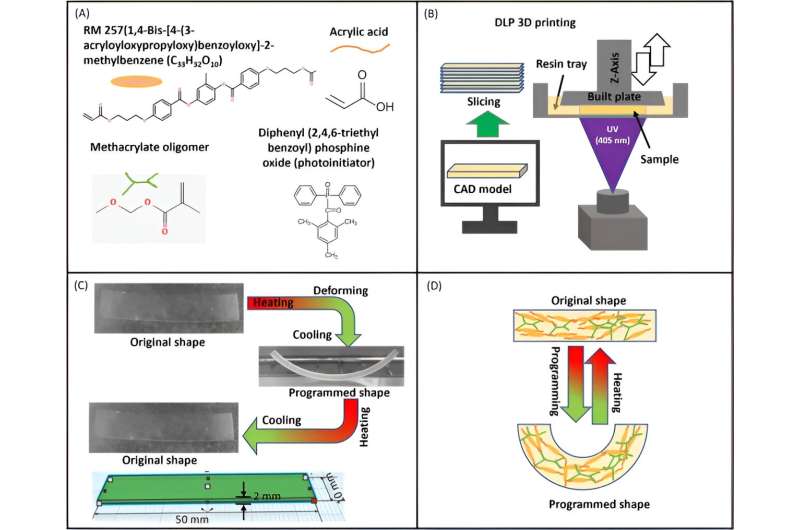

Fahad Alam and a staff of scientists in electrical and laptop engineering, and nuclear engineering on the King Abdullah College of Science and Expertise, Saudi Arabia developed a facile and quick methodology to 3D print shape-memory polymer-based sensible buildings with a digital gentle printing 3D printer and customized resin.

They mixed a liquid crystal (a fabric that may change its form with temperature) with resin, to introduce shape-memory properties to instantly 3D print thermoresponsive buildings—whereas avoiding the complexity of resin preparation. The staff printed the buildings with completely different geometries and measured the shape-memory response. The form-memory polymers may be conveniently ready to be used as sensible instruments, toys, and meta-materials.

The paper is revealed within the journal NPG Asia Supplies.

Form-memory polymers

Form-memory polymers belong to a category of dual-shape sensible polymers that may bear mechanical deformation and return to their unique form in response to environmental parameters. The form-memory polymer restoration is determined by the appliance of exterior stimuli akin to warmth, gentle, electrical energy, humidity, and pH modifications.

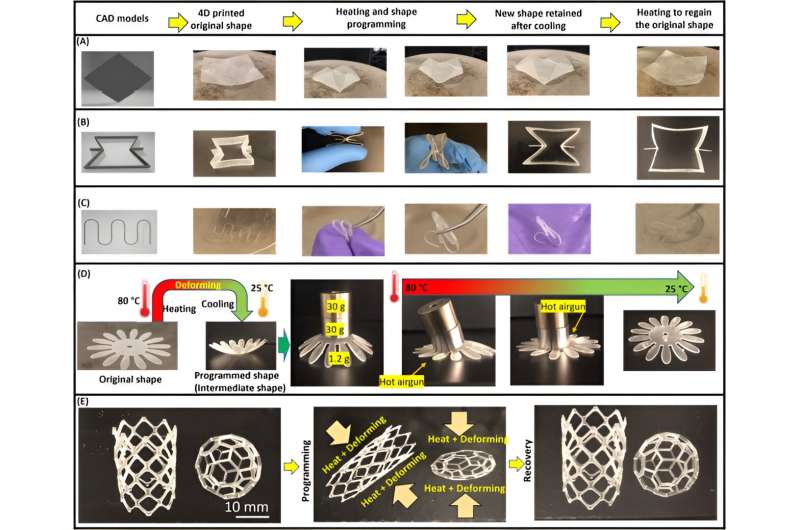

Such supplies are shape-shifting constructs which have gained appreciable curiosity in recent times as a result of their versatility and industrial viability. The analysis staff demonstrated 4D printing shape-memory polymers through digital gentle processing; a 3D printing methodology based mostly on vat photopolymerization. The outcomes highlighted the suitability of 3D-printed advanced buildings for a wide range of functions.

Creating the shape-memory impact

The analysis staff investigated the shape-memory impact of the 3D printed samples by learning the form inducting and recovering course of. The tactic allowed straightforward and high-resolution printing of intricate 3D designs. These constructs are helpful throughout a wide range of functions as versatile sensible patches, size-variable mechanical instruments, and deformable toys. On this work, Alam and colleagues developed a shape-memory polymer based mostly on a liquid crystal blended with a photocurable resin, to develop a semicrystalline polymer and described its mechanism-of-action, based mostly on earlier research.

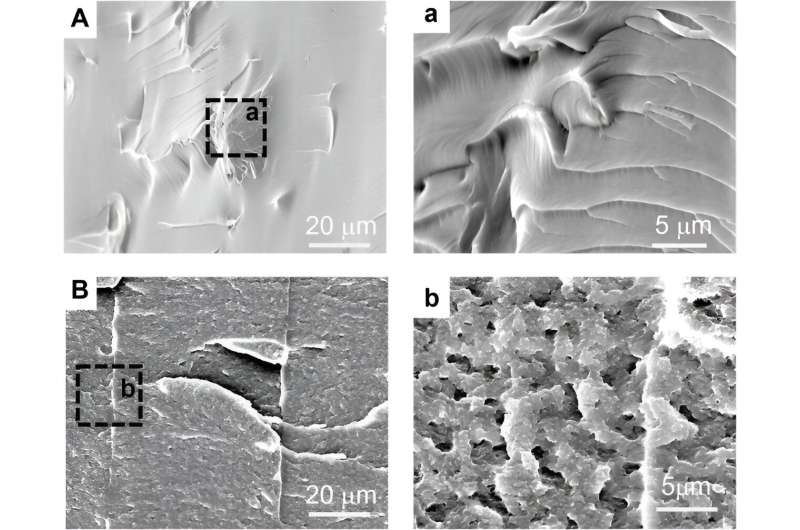

The staff noticed the interior morphology of the 3D printed cross sections with or with out liquid crystals by utilizing scanning electron microscopy. They then noticed the responses of shape-memory polymers relative to their capability to get better after load-bearing. The current work confirmed the affect of 3D digital gentle processing to create shape-memory polymers with 4D results. The scientists quantified the shape-memory response to indicate the restoration angle ratio versus time.

Tunable mechanical properties

The researchers explored the promising functions of 3D-printed sensible reminiscence polymers. To perform this, Alam and colleagues decided the mechanical properties of the supplies by conducting tensile checks on a dog-bone specimen, to indicate how the mechanical properties of printed supplies may be tuned by regulating the form of the lattice buildings.

They confirmed the mechanical tunability of sensible supplies by conducting finite factor simulations, and in contrast the experimental outcomes with tensile checks from the finite factor evaluation. The mechanical performances of the 2D lattices noticed by way of experiment and predicted through simulation agreed. Primarily based on the pliability and stretchability, Alam and staff examined the samples for pressure testing and for joint transferring sensing functions.

To facilitate joint movement through polymer integration, the scientists utilized a nano-silver-based conductive coating as an electrode, which required additional optimization of the printing parameters. The scientists measured the modifications in electrical resistance by stretching and compressing the construction to facilitate motion in sufferers.

The outcomes of resistance measurement of the ready lattice electrode patch confirmed its potential to be used as a wise patch for joint-movement sensing; this may be utilized to a human knee, elbow joint, synthetic limb, or actual limbs to sense motion. Such electrode patches may be personalized to the scale of the affected person beneath straightforward and quick manufacturing processes.

Outlook

On this approach, Fahad Alam and staff introduced a way to 3D print sensible supplies by first utilizing shape-memory polymers for straightforward and quick manufacture by way of digital gentle processing. The scientists personalized the 3D-printed objects to create buildings that modified with time, this is called 4D printing. They achieved this by combining liquid crystals with a resin, and printing it by utilizing a industrial desktop printer. The researchers used the strategy to fabricate a wide range of advanced objects together with lattice patches, foldable toys, sensible packaging, and mechanical wrenches.

The scientists subjected these objects to warmth, to briefly change their form, and for subsequent form restoration functions. The staff used tensile checks to indicate the adjustable nature of shape-memory polymers, to fulfill particular functions in biomedical engineering. Such 3D-printed lattice patches are effectively suited to pressure sensing in joint motion functions. The researchers recorded the modifications in electrical resistance from the 3D-printed sensible patch to detect the motion in synthetic limb joints and arms of sufferers.

Extra info:

Fahad Alam et al, Swift 4D printing of thermoresponsive shape-memory polymers utilizing vat photopolymerization, NPG Asia Supplies (2023). DOI: 10.1038/s41427-023-00511-x

© 2023 Science X Community

Quotation:

Swift 4-D printing with shape-memory polymers (2023, December 22)

retrieved 22 December 2023

from https://phys.org/information/2023-12-swift-d-shape-memory-polymers.html

This doc is topic to copyright. Other than any truthful dealing for the aim of personal research or analysis, no

half could also be reproduced with out the written permission. The content material is offered for info functions solely.