Digital metal powder marketplace qualloy and AddiMap, the “world’s first” digital marketplace for 3D printing process parameters, have announced a strategic collaboration.

Both marketplaces will be combined into one comprehensive platform as a result of this partnership. This platform includes both the sourcing and accessibility of 3D printing parameters as well as the validation of metal powders. The combined offering, it is claimed, will allow users to get the best out of 3D-printing and accelerate the industrialization as well as democratization metal additive manufacturing.

“We are thrilled to collaborate with AddiMap and combine our strengths to create a comprehensive solution for the AM industry,” commented Yannik Wilkens, Co-founder of qualloy. “Through this partnership, we aim to further enhance the user experience by providing seamless access to AddiMap’s extensive printing parameters database, empowering users to unlock the full potential of additive manufacturing.”

Combining two digital marketplaces

This collaboration is said to bring together two “cutting-edge” platforms that “perfectly” complement each other.

qualloy’s digital metal powder marketplace provides a platform where buyers and sellers can easily connect and conduct transactions. Qualloy’s intelligent search algorithm is used to accomplish this. This, it is claimed, streamlines the powder sourcing and allows users to find the best metal powders to suit their needs among a wide range of certified suppliers.

Qualloy enables users to freely switch among different metal powder suppliers. So, users are able to optimize the price, delivery and quality of their metal powder while still maintaining an efficient and transparent purchasing process.

According to Wilkens, “With qualloy, we have simplified the market for metal powders, enabling buyers to find the perfect match for their printers quickly.”

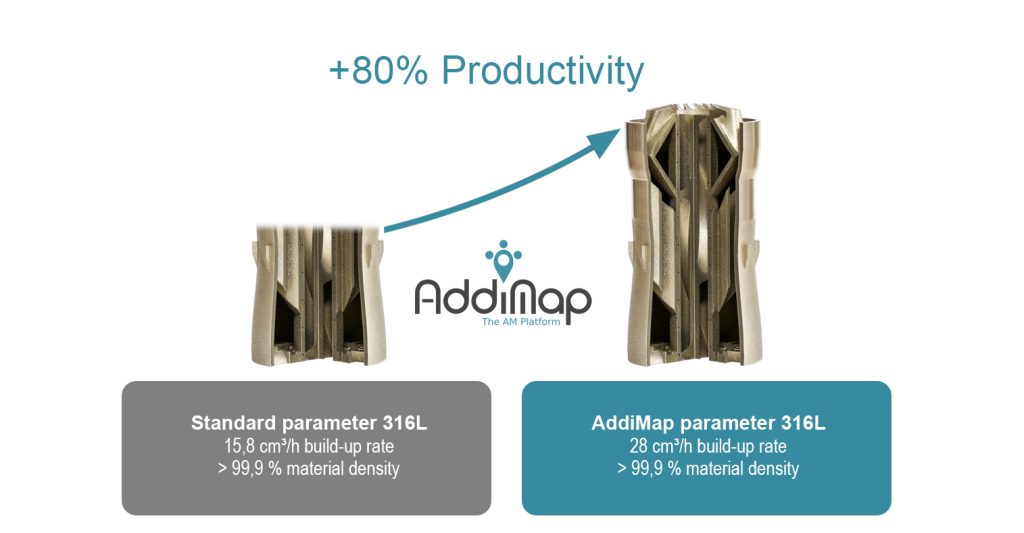

AddiMap, developed by Rosswag Engineering, a metal 3D-printing service bureau, and NuCOS Software Company was beta launched last year. AddiMap’s plug-and-play printing parameter platform is said to significantly reduce the time and resources required for parameter development and qualification processes.

By accessing AddiMap’s parameter library, users can transition from digital models to physical products without requiring extensive parameter studies. AddiMap claims that their product accelerates industrialization of metal-additive manufacturing by democratizing knowledge and resources.

Gregor Graf, the initiator of AddiMap has stressed the importance for cost-reduction and collaboration in accelerating adoption of metal 3D Printing. “Cooperation is the key to leverage the full potential of Metal AM. Less costs and more materials will lead to faster industrial adoption.”

“With AddiMap, we aim to provide users with a vast range of process parameters, enabling them to increase productivity, optimize properties, explore new materials and streamline their AM operations,” added Graf.

The two companies claim that their collaboration is a landmark in further simplifying additive manufacturing. It streamlines the procurement of metal particles and provides access to an extensive database of 3D printing parameters. These companies claim they are driving industrialization and democratization in additive manufacturing. They also promote growth and innovation.

Industrializing additive manufacture

In the 3D printing world, the theme of industrializing additive manufacturing is common. Earlier this year, global standards developer ASTM International’s Additive Manufacturing Center of Excellence (AM CoE) added a number of new members to its Consortium for Materials Data and Standardization (CMDS) program. Given that 3D printing materials are key to the additive manufacturing workflow, a notable aim of the CMD is to “accelerate the industrialization and full adoption of AM technologies.”

BMW announced its Industrialisation and Digitalisation of Additive Production (IDAM), a project that aims to digitally connect automotive 3D printing production lines, as a success last year. The initiative was launched in 2019 and established two digitally connected automotive 3D-printing production lines in Bann, Germany. These manufacturing suites now have the ability to produce around 50,000 components per year without any manual inputs.

Subscribe to the Newsletter 3D Printing Industry News You can also follow us on Twitter to stay up-to-date with the latest 3D print news. Follow us on Twitter. TwitterYou may also like Facebook Page and Subscribe to the 3D Printing Industry on Youtube Channel to access exclusive content.

You can find out more about the industry by visiting their website. Are you interested in working in the additive manufacturing industry? 3D printing Jobs View a variety of roles available and start your career.

The featured image displays the AddiMap and qualloy partnership banner. Image via Rosswag Engineering.