Mito Plus 3D Bio Printer – Tissue printing

BIo-printing is a technique for tissue replication that supports or nurtures living cells. This technique can be used as an alternative to organ transplantation. It is possible to create functional human tissues like skin using specially engineered biomaterials and bio-inks.

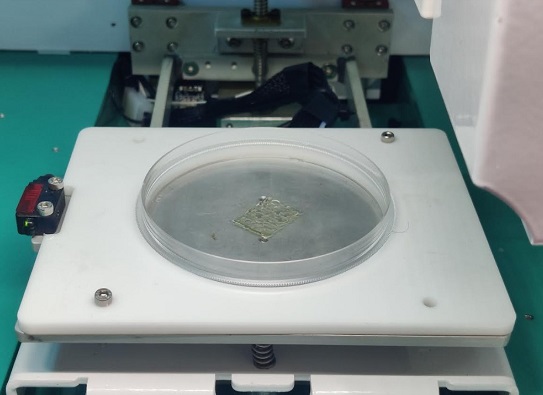

An indigenous state-of-the-art 3D Bio-Printer ‘Mito Plus’ launched by Indian Tech Startup Avay Biosciences has been found to be helpful in printing human tissues. At the Bengaluru Tech Summit which took place between 16 and 18 November 2022, Mito Plus was unveiled. The prototype of Mito Plus, which was built at Bangalore’s Indian Institute of Science (IISc), was installed by NIRF Rankings.

Mito Plus, a 3D bio-printer that is more advanced than the original prototype was developed using inputs from Dr Bikramjit Basu’s research lab at IISc. It was co-founded by Avay, an IIT Madras alumnus. It is among the top 3D printers in India. Avay Biosciences offers a complete range of hardware and software development to provide end-to-end Bio 3D printing solutions for India.

Bio-printing allows for tissue replication and supports or nurtures living cells. This technology is an alternative to organ transplantation and could be used to produce functional human tissues, such as skin, using biomaterials or bioinks that are engineered to print artificial living tissue.

Manish Amin, Chief Executive Officer, Avay Biosciences, said, “MITO plus is an advanced bio-printer at its price range which can be used to print a wide range of biomaterials. This printer features an inbuilt UV curing, HEPA filter, as well as temperature control. The print-head can be cooled to 4°C and the print bed heated to 80°C. MITO plus can be used for pharmaceutical drug discovery and drug testing applications, it can also be used in cancer biology and cosmetology applications.”

Bio-printers operate in the same manner as other 3D printers. The only difference is that instead of delivering material such as metal or plastics, bioprinters deposit layers of biomaterials. These biomaterials may contain living cells. They can be used to create complex structures such skin tissue, liver tissue, and so on. The science and technology of 3D bioprinting are a gift to humanity. Many challenges remain to be overcome. ‘’There is still a long way to go before we can create fully functioning and viable organs for human transplant,” Amin explained.

“We are working on having our printers develop skin – the most common type of layered tissue that could help victims of severe burns. These tissues can also be used for toxicology screens and other testing mechanisms,” said Suhridh Sundaram, Chief Operating Officer, Avay Biosciences.

Bio-printing typically uses polymers that attempt to replicate the extracellular matrix (ECM), native to a specific cell. Because future research is dependent on the availability of affordable bio-printers, it is vital that they are available. Bioprinting, which can be used with animal cells, can also be used to make artificial meat. This is a space-age food vision.

The tech startup has collaborated with IIT Madras and IISc Bangalore as well as premier Research and Development institutions like IIT Madras and IISc Bangalore.

India Science Wire

ISW/USM/Avay Biosciences/Bio-printing/ENG/18/11/2022