The CHU de Brest enhances surgical preparation by the utilization of superior Stratasys 3D printing know-how, which creates patient-specific anatomic fashions. J5 MediJet 3D printer’s multi-material, multi-color capabilities allow surgeons to supply real looking fashions to plan complicated surgical procedures, enhancing planning, coaching, and affected person outcomes.

Content material offered by Stratasys

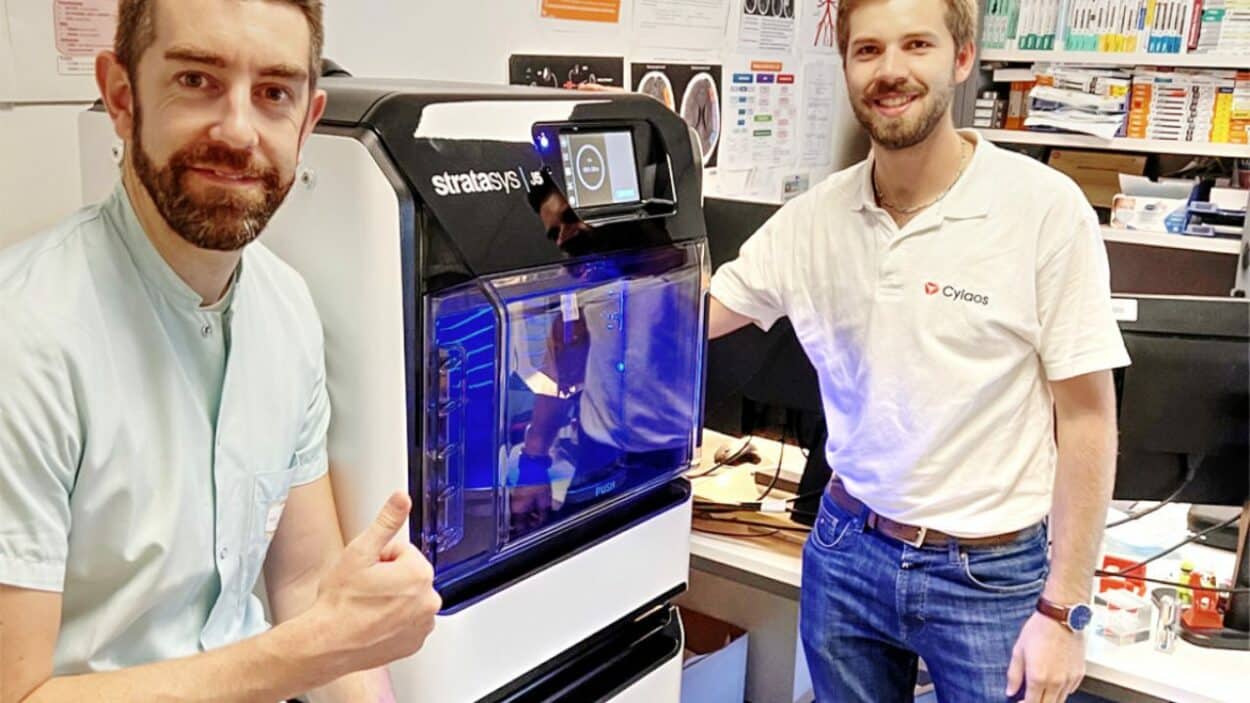

France-based Regional College Hospital of Brest (CHU de Brest) is witnessing substantial enhancements in pre-surgical planning procedures following the implementation of a brand new 3D printer by Stratasys’ associate reseller, Cylaos.

The set up offers surgeons extremely correct and detailed 360-degree patient-specific anatomic fashions previous to the precise operation, which can enhance surgical dangers and scale back time within the working room.

In line with Samuel Guigo, radiology and 3D printing technician on the CHU, the real looking sophistication of the 3D printed fashions produced with the all-in-one, multi-material, multi-color J5 MediJet over earlier single-material, single-color choices is transformational and units a brand new customary for medical modeling.

“The accuracy we now get pleasure from with the J5 3D printed fashions means our surgeons are much better geared up and ready earlier than going into theater, which considerably and quantifiably reduces surgical-related dangers by improved security.”

Guigo provides:

“When making ready a vascular surgical procedure, for instance, millimetric precision is necessary. With the J5 MediJet, not solely can we obtain this, however we now have the pliability to re-print the fashions to iterate and obtain optimum outcomes, reproducing them with full consistency, as required. We had been merely unable to do that beforehand.”

The usage of Stratasys’ superior 3D printing know-how is, explains Guigo, a vital issue contributing to the standard of the anatomical fashions the hospital can produce. This, he says, is underscored by the Elastico TM photopolymer materials.

“We will produce fashions on the MediJet with far higher realism than our different 3D printing applied sciences permit. With the Elastico materials, for instance, the haptic feeling and floor smoothness replicate the affected person’s delicate arteries rather more intently.”

The shortcomings within the hospital’s current various applied sciences additionally meant that the manufacturing of some fashions needed to beforehand be outsourced to exterior suppliers. Nonetheless, with a stage of high quality that fell in need of the hospital’s necessities, along with a mounting want to raised handle rising volumes, the acquisition of the in-house J5 MediJet made logical enterprise sense.

Enhancing Coaching and Affected person Care

Past pre-surgical preparation, using patient-specific 3D printed medical fashions produced on the J5 MediJet for on-demand coaching can enhance affected person outcomes by decreasing problems and reducing general restoration time and size of hospital keep.

As well as, with a extremely correct patient-specific 3D printed medical mannequin, surgeons can higher clarify particular pathologies and procedures to sufferers previous to surgical procedure, which has been confirmed to enhance a affected person’s therapeutic understanding and satisfaction.

“The MediJet implies that we’re profitable in each space. We now have higher administration of development necessities and have addressed high quality points, whereas additionally enhancing processes and academic practices.”

Since its set up, using the J5 MediJet has quickly expanded to completely different hospital departments, together with Interventional neuroradiology, orthopedic surgical procedure, vascular surgical procedure, and neurosurgery, in addition to biomedical companies.

Trying forward, the CHU’s subsequent purpose is to arrange a devoted 3D printing arm that may handle the wants of the hospital’s departments, analysis workforce, and coaching. With the hospital targeted on championing the know-how’s common use throughout the medical sector, there may be additionally a imaginative and prescient for producing 3D-printed anatomical fashions for different hospitals, in addition to for biomedical engineering colleges.