Italy-Based Pusterla Acquires Two US Box Makers, Supremex Executes Box Strategy; and more…

The simple box. It was inevitable. The market for box manufacturing has heated up and in the most recent month the purchase of box printing companies has outpaced the number of deals involving label printing companies for the first time in our eleven?plus years of tracking and commenting on M&A activity in the printing, packaging, and related industries. (See Label Roll-Ups are Red Hot; Are Folding Cartons Next? – March 2022.)

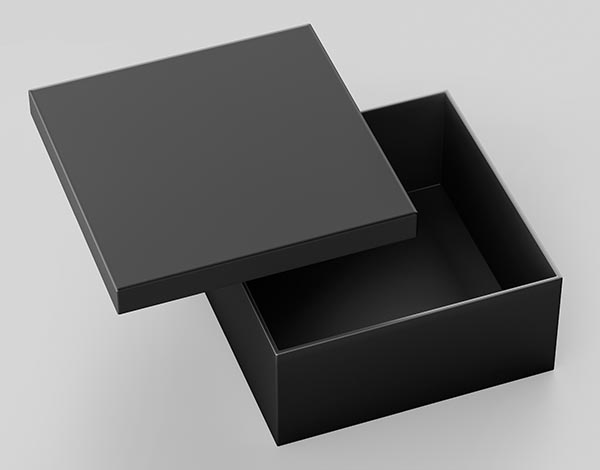

The Rigid Box

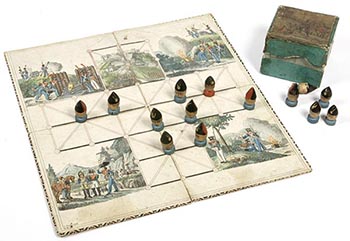

A set-up box is the original fiber-based box. The name refers to the simple form of these boxes. These boxes are formed by wrapping, tacking, and glueing paper around stiff cardboard to create a rigid container that can be packed and shipped. It is hard to trace the origin of the box. However, many sources suggest that it was made by a German company in 1817. The Game of BesiegingAn early war strategy board game. An alternate history credits the creation of the first commercial paperboard box to an English firm, M. Treverton & Son, curiously asserting that production began in the same year as the German claim, 1817. The rigid box remained the dominant fiber-based container for nearly a century. Around 1900 saw the development of more efficient box production methods. The rigid box became less popular as a volume utilitarian solution. Today, rigid boxes are used most commonly to package high-end and special items. They can be decorated with foils and coated with gloss or soft-touch finishes.

A set-up box is the original fiber-based box. The name refers to the simple form of these boxes. These boxes are formed by wrapping, tacking, and glueing paper around stiff cardboard to create a rigid container that can be packed and shipped. It is hard to trace the origin of the box. However, many sources suggest that it was made by a German company in 1817. The Game of BesiegingAn early war strategy board game. An alternate history credits the creation of the first commercial paperboard box to an English firm, M. Treverton & Son, curiously asserting that production began in the same year as the German claim, 1817. The rigid box remained the dominant fiber-based container for nearly a century. Around 1900 saw the development of more efficient box production methods. The rigid box became less popular as a volume utilitarian solution. Today, rigid boxes are used most commonly to package high-end and special items. They can be decorated with foils and coated with gloss or soft-touch finishes.

The Corrugated Box

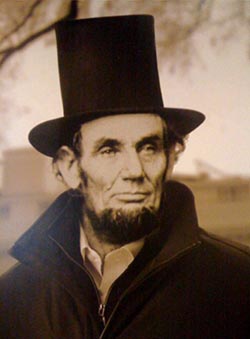

Tall top hats were a fashion trend in 1856. Edward G. Healy (Hater trade) and Edward E. Allen (Haster trade) set out to find a material to maintain the tall shape while being flexible enough to fit individual noses. Their solution was to fold paper in pleats. This gave it strength and wavy texture. The invention was patented in England by the pair, but they didn’t make the leap to use their invention to create shipping boxes. American ingenuity was behind the next step forward in the form of a US patent filed in 1871 by Albert L. Lyons for “an improvement in paper for packing” which described the use of corrugated, crimped, or bossed forming of paper to create an effective cushion for the contents being packed. Three years later, a machine for producing large quantities corrugated paper was invented. Oliver Long, another inventor in 1871, added the liner to the second side of the machine, trapping corrugation in the middle. The result is the corrugated paper we know today. The first corrugated box, which was produced in the USA in 1895, replaced the wooden crates and boxes that were used to ship goods.

Tall top hats were a fashion trend in 1856. Edward G. Healy (Hater trade) and Edward E. Allen (Haster trade) set out to find a material to maintain the tall shape while being flexible enough to fit individual noses. Their solution was to fold paper in pleats. This gave it strength and wavy texture. The invention was patented in England by the pair, but they didn’t make the leap to use their invention to create shipping boxes. American ingenuity was behind the next step forward in the form of a US patent filed in 1871 by Albert L. Lyons for “an improvement in paper for packing” which described the use of corrugated, crimped, or bossed forming of paper to create an effective cushion for the contents being packed. Three years later, a machine for producing large quantities corrugated paper was invented. Oliver Long, another inventor in 1871, added the liner to the second side of the machine, trapping corrugation in the middle. The result is the corrugated paper we know today. The first corrugated box, which was produced in the USA in 1895, replaced the wooden crates and boxes that were used to ship goods.

The Folding Carton

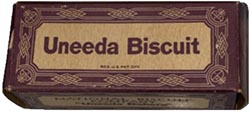

Robert Gair, an immigrant from Scotland to America, was working in Brooklyn’s printing shop on a small order for seed bags. According to the legend, Gair’s diemaker did not correctly set the creasing rule and left the blade too high. Before the mistake was discovered, the miscreant die was able to cut through thousands upon thousands of seed packets. The whole lot was then wasted. Gair was able to cut and fold paper in one operation. Although this may seem obvious today, the scoring was done using a press while the cutting was done using a guillotine cutter. Gair used his knowledge to create heavier paperboard. It was a huge increase in productivity. The new product was easier to produce and could be glued and packed flat for shipment. Final assembly and erection took place at the factory. The product was then inserted into the box. Early converts to the new mass-produced foldable cartons included the Great Atlantic & Pacific Tea Company, Colgate, Ponds, and tobacco manufacturer P. Lorillard. Gair received a two-million order for his precut and pre-creased cardboard boxes in 1896 for Uneeda Biscuits, a company that was then known as the National Biscuit Company. The folding carton quickly overtook the wooden cracker and tin boxes. Eventually further popularized by Kellogg’s for the sale of cereals to the masses, the folding carton had arrived. Gair was a great success and built seven factories in Brooklyn’s Dumbo area. His name is still visible on many of the factory facades.

Robert Gair, an immigrant from Scotland to America, was working in Brooklyn’s printing shop on a small order for seed bags. According to the legend, Gair’s diemaker did not correctly set the creasing rule and left the blade too high. Before the mistake was discovered, the miscreant die was able to cut through thousands upon thousands of seed packets. The whole lot was then wasted. Gair was able to cut and fold paper in one operation. Although this may seem obvious today, the scoring was done using a press while the cutting was done using a guillotine cutter. Gair used his knowledge to create heavier paperboard. It was a huge increase in productivity. The new product was easier to produce and could be glued and packed flat for shipment. Final assembly and erection took place at the factory. The product was then inserted into the box. Early converts to the new mass-produced foldable cartons included the Great Atlantic & Pacific Tea Company, Colgate, Ponds, and tobacco manufacturer P. Lorillard. Gair received a two-million order for his precut and pre-creased cardboard boxes in 1896 for Uneeda Biscuits, a company that was then known as the National Biscuit Company. The folding carton quickly overtook the wooden cracker and tin boxes. Eventually further popularized by Kellogg’s for the sale of cereals to the masses, the folding carton had arrived. Gair was a great success and built seven factories in Brooklyn’s Dumbo area. His name is still visible on many of the factory facades.

All Types of Boxes

Italian packaging printing company Pusterla 1880 produces high-end packaging for luxury brands in the fragrance, cosmetics, wine & spirits, and gourmet food markets. The company, which has factories in Italy, Italy, Moldova, Tunisia and the UK, entered the US market by simultaneously purchasing two rigid box packaging manufacturers. Pusterla announced that it had acquired Taylor Box Company in Warren, Rhode Island and Burt Rigid Box, Oneonta, New York.

SupremeX, a Canadian publicly traded company that has its roots in envelope manufacturing, has expanded its reach into box manufacturing with the acquisition by Impression Paragraph. This folding carton printing and manufacturing firm with two Quebec facilities, Impression Paragraph is a Canadian folding carton printing company. The acquired company produces point-of-sale retail displays for the cosmetic, pharmaceutical and food confectionary markets. The acquisition marks Supremex’s fifth move into the folding carton business, following the 2021 acquisition of Vista Graphic Communications in Indianapolis, Indiana,* both acquisitions examples of the company’s laser-focused execution of its strategic diversification plan to acquire packaging companies and supplement its legacy core envelope business. Supremex is not neglecting envelope business. In fact, Supremex acquired Royal Envelope’s two Chicago-area manufacturing facilities. The company focuses primarily on the production of high-end, highly decorated envelopes used in direct mail.

Oliver Packaging purchased Tap Packaging + Design, its first company acquired under the sponsorship of Tenex Capital. The acquired company manufactures folding cartons. In a slight departure from Oliver’s original focus on folding cartons the acquisition adds rigid boxes to its mix and micro flute corrugated packing. Tenex Capital acquired Oliver from Pfingsten Partners, in what was known as a secondary buyout. Pfingsten bought Oliver in 2016, but it was privately owned, managed by the Oliver family, and maintained control in the Cleveland area. Oliver Printing, the company’s original name, had successfully transformed from a commercial printer to one that was a focussed on folding cartons. This included structural design and printing. Pfingsten was the first institution to purchase Oliver Printing. He rebranded the company and added four acquisitions that have made Oliver a major player in the folding carton market. Among these acquisitions was the venerable Disc Graphics in Long Island, New York. This is where Oliver Packaging is now headquartered.

GPA Global has announced the acquisition by the Cosfibel Group based in Paris. The acquired company has factories in Spain and Belgium and specializes in serving prestigious high-end brands with rigid box sets, gift packs, secondary packaging and product presentations in the beauty, wine & spirits, gourmet foods, and high fashion markets. Consistent with GPA Global’s strategy of combining in-house manufacturing with outsourced specialty purchasing, Cosfibel touts its “make & trade” approach to fulfilling its customers’ packaging requirements. (See GPA Global Emerges as Packaging Consolidator – December 2021.)

S. Walter Packaging Group is a portfolio company owned by Larsen MacColl Partners. In 2014, Pulver Packaging was acquired by Larsen MacColl Partners. Pulver Packaging is a manufacturer of folding cartons located in Elk Grove, Illinois. Pulver will bring design, sourcing printing, fabrication enhancement, warehousing and inventory management to its new parent. The S. Walter Packaging Group includes a specialty division, Bags & Bows, which serves the retail market with bags, stock size boxes, tissue paper, gift wrap, and as the name suggests, ribbons and bows. LPI, formerly known as Letterhead Press, offers highly specialized finishing services such as stamping holographic images and foil stamping.

Welch Packaging Group, the roll-up that has focused exclusively on corrugated products, is back in acquisition mode after a two-and-a-half-year pause in M&A activity. Welch recently announced the acquisition of Knoxville Box and Container. The acquired company’s product line, corrugated cartons, is consistent with every company that Welch has acquired in the 37 years since the owner established the company with only four employees and rudimentary box-making equipment. Welch Packaging has now expanded its reach to the Midwest and South-Central regions with this acquisition. Welch Packaging now operates from more than 12 manufacturing locations and 3 distribution centers. Welch Packaging employs over 1,200 people. (See Catching the Wave in Corrugated Cartons – February 2020).

* Graphic Arts Advisors, publisher of The Target ReportVista Graphic Communications’ exclusive advisors on this transaction was,

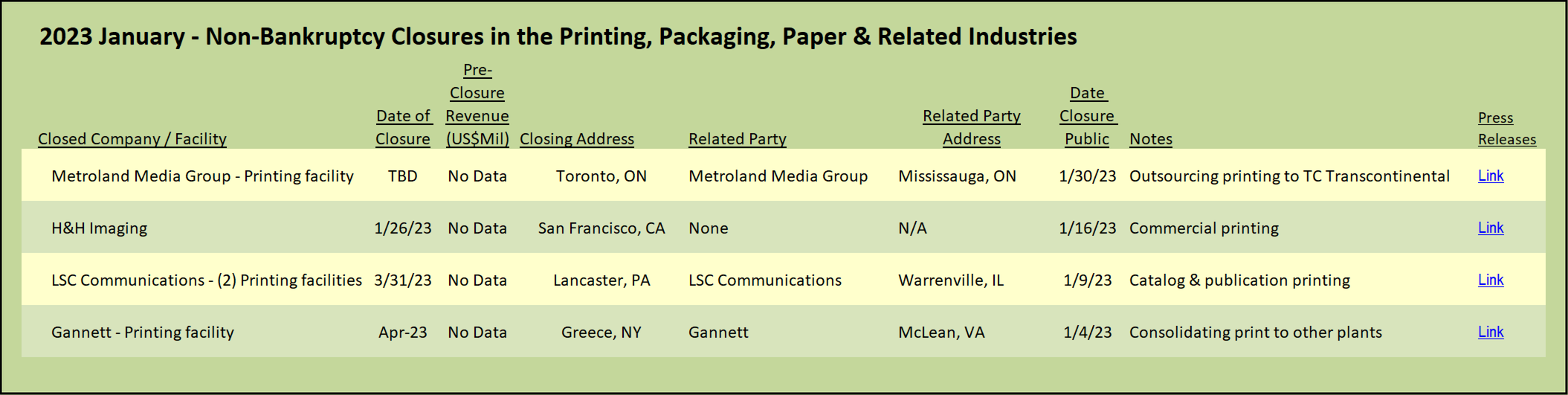

You can view The Target Report online. It includes deal logs, source links, and more for January 2023.

www.graphicartsadvisors.com