The 3D Printing Industry Awards 2022 Voting is now open for shortlists. Vote now to determine who will win the 2022 3DPI Awards. Vote now to have your say.

3D printer OEM Stratasys demonstrated a fully integrated 3D printing and post processing platform at Formnext.

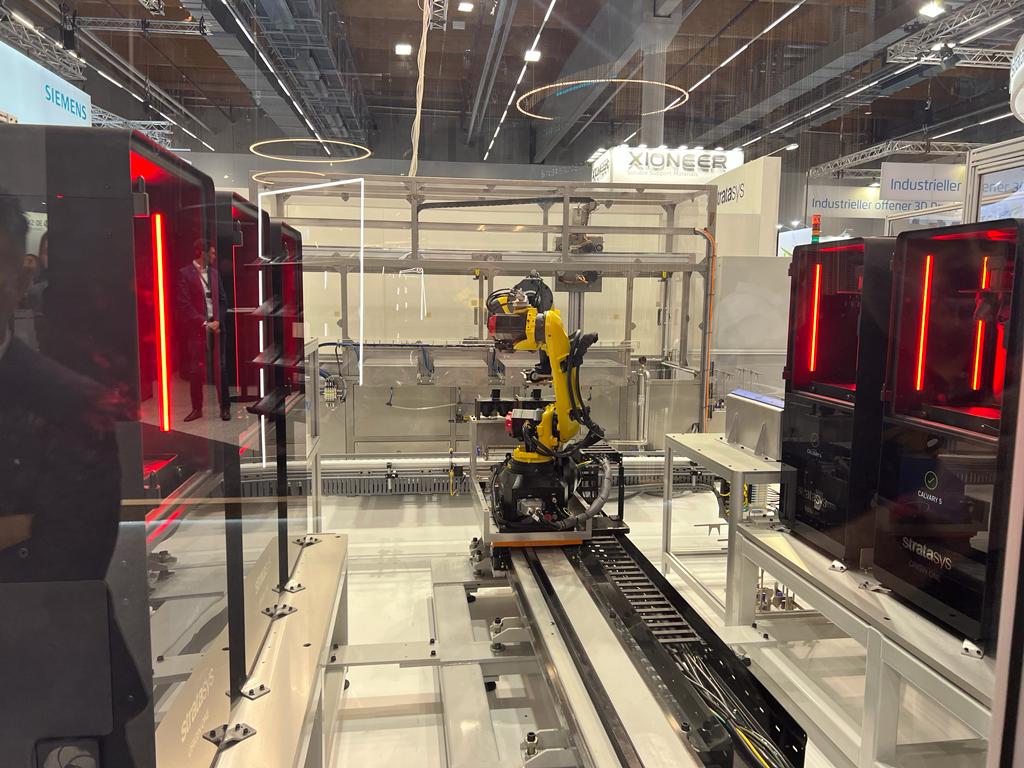

Stratasys’ P3 Automated Production Cell incorporates a string of Origin One systems, as well as robotics, conveyors and part finishing equipment. Once prints are ready, the cell’s mechanical arm is able to collect and transport the relevant build plate to an in-built post-processing facility, with the UV curing and drying functionality to wash, rinse and cure them as necessary.

Developed with Calvary Robotics, the setup was initially designed to show how it’s possible to harness robotics as a means of driving down manufacturing costs and scaling 3D printing. That said, the system is also directly configurable to customer needs, and Stratasys’ partner has said it’s hoping that the drawing attention to the setup at Formnext, will attract new clientele to its automated production portfolio.

Stratasys’ P3 Automated Production Cell

Debuted at Formnext, Stratasys’ demonstrator production cell revolves around the P3 technology bought via its acquisition of Origin nearly two years ago. Origin’s Programmable Photopolymerization (P3) process allows for the printing of parts with voxel-level control, in a way that enables users to extract different mechanical performances from a material, and customize parts for specific applications.

Origin One, which is powered by P3 technology, was also designed to enable production at scale. Origin says its system does so through pairing “unmatched part-to-part consistency” with a high throughput, and the incorporation of a modular design which is both optimized for batch production, and enables capacity to be increased where needed.

With its P3 Automated Production Cell, Stratasys is now attempting to fully realize the machine’s high-throughput promise, via its incorporation into a fully-automatic production workflow. The setup works with a robot arm that picks up print plates on demand and then transfers them via a winding conveyor for sorting or post-processing.

Once a cycle has been completed, the platform’s robotic arm is then capable of cleaning, emptying and returning the build plate to the relevant printer, ready for the next batch to begin. While Stratasys says the cell has been built as part of a “demonstration project” to “improve the efficiency of operating fleets of Origin One 3D printers,” Calvary Robotics does offer similar setups on a commercial basis.

Stratasys unveiled its uniquely-integrated platform as part of its ‘Let’s Talk Manufacturing’ display at Formnext. This also saw the firm announce the validation of new materials from the likes Arkema, Victrex and Covestro for its systems, and the introduction of the ‘UILA’ EV concept, a partially-3D printed four-wheeled two-seater designed as a sustainable transport solution.

“Over the last two and half years, our focus has expanded from building up our hardware portfolio to working with key industry partners to develop a wide range of use-case-specific solutions,” said Andy Langfeld, President of EMEA at Stratasys. “These complete solutions encompass hardware, software, materials, and services that create new business opportunities for our customers.”

“We continue to accelerate cutting-edge developments in additive manufacturing and advance our strategy of providing the best and most complete polymer 3D printing portfolio in the industry.”

Of course, Stratasys’ P3 demonstrator isn’t its first to be unveiled at a major trade show. In 2017, Stratasys’ Continuous Build 3D Demonstrator was introduced at Rapid+TCT. Although the setup is designed to work with FDM systems, rather than resin ones it was also built to achieve the same goal: to link machines that can unlock fully-automated 3D printed parts.

Elsewhere in the industry, 3D Systems’ Figure 4 Production systems can also be connected into a 3D printing production line, with just one control unit operating multiple cells at once. According to the company, its machines allow users to “grow capacity alongside demand,” from a standalone printer for rapid prototyping and low volume production, to a “fully-automated, integrated factory solution.”

Follow this link for all the Formnext 2022 news.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter Follow us on Twitter You can also like our page Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, and video shorts.

Are you interested in a job within the additive manufacturing sector? Visit 3D printing jobs For a list of available roles in the industry.

Featured image shows Stratasys’ P3 Automated Production Cell at Formnext. Mael Duportal.