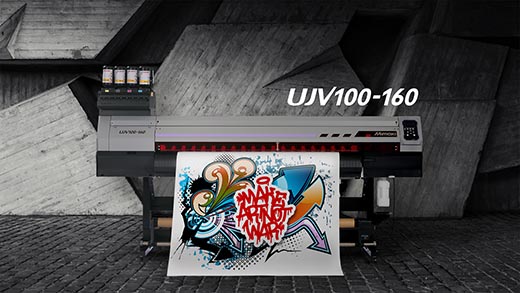

UV-LED technologies such as the Mimaki UJV100–160 offer a durable process without limiting the range of applications.

By Mustafa Okanovic, Sr. Mimaki Europe, Product Specialist

Digital printing has seen a rapid adoption over the past decade. This technology is now a popular option for future industrial-scale printing. There is much debate about the best type and use of ink in this industry. The decision will depend on many factors.

When investing in a printer, press or other recurring investment, inks should be considered, especially for large-scale operations. Recurring costs are not only expensive, but also increase CO2 emissions. It is essential that the printer creates added value, has a wide range of applications, and the ink be of high quality to start with in order to maximize profits. You might also consider Latex and UV-LED printers.

UV LED or Latex Printing – What is the difference?

Latex inks can be water-based, pigmented inks with small particles of latex. This is a form plastic. After the ink has been applied to the product, heat is used for the removal of the water and to dry the pigment. UV-LED inks, on the other hand, are not water-based and instead use UV light to dry the substrate.

The Benefits of Using a Balanced Approach:

1. Sustainability

As European goals become more ambitious, sustainability is becoming a key aspect.[1] Encourage industries to reduce CO2 emission. Both UV-LED inks and Latex inks both have their advantages and disadvantages in this area. The overall process is sustainable. UV-LED inks require up to nine times2 less energy throughout the printing process than Latex inks, due to Latex inks’ water-based composition requiring an additional curing and drying process. A curing heater is required for latex printers. Products made with UV-LED ink cannot be taken to the post processing machine until they have been properly dried by a curing furnace. The whole process is more time-consuming, expensive, and less eco-friendly. Mimaki’s JV400LX Series of printing technology has created Latex inks which can be cured at low temperatures to combat this problem and minimize energy consumption. UV-LED inks are able to cure immediately with only a fraction the energy of Latex. This allows for huge energy savings, as well as a tenfold decrease in CO2 emissions.

Both inks are safe after curing. Due to their water-based composition, latex inks have an advantage. UV-LED inks offset this by releasing fewer VOCs.

All Mimaki’s UV and Latex inks have been certified ECO GreenGuard Gold. These products are safe to use in all environments. PSPs should be aware that the trend towards more sustainable production methods is increasing as people become more conscious of climate change. This will continue to be an important consideration moving forward.

2. Cost-Effectiveness

The UV-LED printer is the clear winner here. It has a lower initial investment, and UV inks costs less per liter than latex. UV-LED printers have a 3x lower ink consumption than Latex and can help increase sales margins.

UV-LED curing technology is versatile. It doesn’t produce heat and so can be used with a wide range of materials. UV-LED can print on most materials without any special coating, unlike Latex which only allows for heat-resistant and expensive materials. UV-LED transparent inks can be used to create luxury and high-profit glossy or matte applications. They are specifically designed for multi-layer printing, printing with either white or colour inks.

It is possible to reduce wastage and both save money as well as help the environment. UV-LED inks offer a better option as they are 17% more efficient than Latex inks. This is due to the fact that UV-LED inks require less flushing between jobs.

UV-LED printheads are more durable than Latex printheads which need to be replaced after 1.5 litres have been used. Mimaki’s UV printheads come with a minimum 1-year warranty. This warranty covers all printing volumes during warranty period.

3. Quality of Output

Colour vibrancy is where Latex Printing comes out on top. However, the overall quality of detail such as skin tones or fine print details as well as colour matching for repeat orders and colour matching are definitely on the UV-LED Printer side. Unique technologies such as the Mimaki Varable Dot technology allow for less graininess and sharp tonal jumps. This creates a photo-quality image.

UV-LED inks are extremely durable thanks to their unique curing technology. UV-LED printed products, such as floor graphics can often be used right away after printing unlike Latex inks that require lamination for outdoor or scratched applications. This further reduces the time and costs involved in creating a final product.

Conclusion

Different PSPs will place different priorities when choosing a printer. These factors will also vary depending on the application they want to print. For printers that only have a few materials to work with, latex is able to create vibrant, colourful applications. UV-LED technology is clearly ahead of the pack in terms sustainability, cost-effectiveness and flexibility. It also offers scratch resistance, quality, and scratch resistance. UV-LED technology offers a faster return on investment due to its combination of advantages.

[1] https://sdgs.un.org/goals

2 According to Mimaki‘s internal evaluation