Climate change is undoubtedly one of the most pressing issues facing mankind today. Global warming is being caused by excess carbon dioxide in the atmosphere, which causes a greenhouse effect. Many scientists are trying to solve the problem. A new study from North Carolina State University suggests that additive manufacturing might play a significant role. Researchers have shown it’s possible to create carbon dioxide capture filter using 3D printing.

Global warming is caused by excess carbon dioxide released into the atmosphere due to industrial processes, and in particular oil use. Indeed, an annual report from the National Oceanic and Atmospheric Administration (NOAA)’s Global Monitoring Lab, the global average atmospheric carbon dioxide was 417.06 parts per million in 2022, a new record and an over 50% increase from pre-industrial levels. In addition, the oceans have become more acidic by 30% due to carbon dioxide absorption. The problems are difficult to solve. While we’d like to stop using fossil fuels that contribute to this problem, some fear it will disrupt their way of living. The search is on for ways to capture and store carbon that’s already in the air.

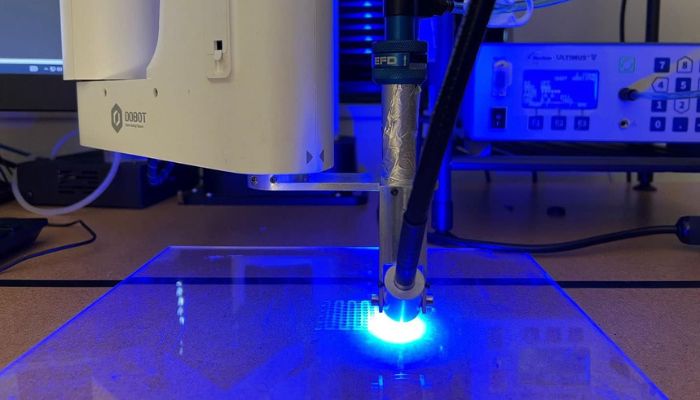

3D-printed carbon dioxide capture filters (photo credit: Sen Zhang, Jialong Chen, NC State).

Researchers at NC State recently demonstrated that 3D printing can be used to create carbon dioxide filters. More specifically, a 3D-printed material capable of retaining carbonic anhydrase. This is because the enzyme speeds up the reaction between carbon dioxide and bicarbonate. Jialong Shen, an Assistant research professor of textile engineering, chemistry and science at NC State and the study’s lead author explained, “This manufacturing process, using 3D printing, makes everything faster and more precise. This material can be made by anyone with a 3D printer and the necessary raw materials. We formulated the hydrogel in a way that would be mechanically strong enough to be 3D printed, and also extruded into a continuous filament.”

3D Printing Carbon Dioxide Capture Filters

The researchers chose 3D printing to create the carbon dioxide filters because it is a more flexible and faster method. They used a method that is similar to material jetting, but seems to be a mix between 3D extrusion printing and photopolymerization. This was done by creating a 3D printing “ink” out of two different organic compounds and carbonic anhydrase. The researchers were then able to print filament-like threads of hydrogel onto a grid in two dimensions while solidifying their solution with UV lights. It was crucial to create a hydrogel which could be both extruded into a continuous thread and be strong enough to 3D print.

Overall, they seem to have had success. According to a press statement, in fact, in small-scale experiments, they were able capture 24% carbon dioxide from a gas mixture. The fact that this test was smaller than the previous ones could explain the lower results. Moreover, the filters can be made larger and different shapes in order to stack them in a large cylinder to improve capture efficiency. The filtration was tested for durability and retained 52% its original carbon capture performance even after 1,000 hours.

The study’s co-corresponding author and associate professor of textile engineering, chemistry and science at NC State, Sonja Salmon, concludes: “This work is still early stage, but our findings suggest there are new ways to make materials for carbon capture devices. We’re offering hope for carbon capture.” The published study HERE contains more information.

*Cover Photo Credits: Image by wirestock on Freepik